Berkshire Custom Biopharmaceutical Isolator for Biopharma

Client:

Berkshire

Facility:

Biopharmaceutical Isolator

Application:

Biopharma

Location:

Lee, MA

Streamlined Biopharmaceutical Isolator Solution

Berkshire Sterile Manufacturing needed an isolator with a fast decontamination cycle for small batch filling, while maintaining ISO-5 sterile conditions for their Colanar filling device.

Project features

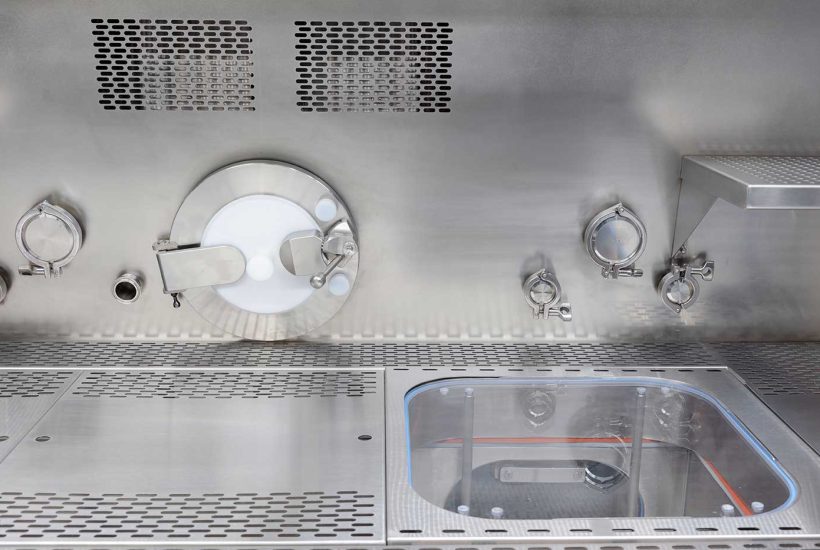

Size: 8’ isolator

Layout configurations: VHP integrated, multiple air gasket doors, pneumatic lift

Features: Integrated hydrogen peroxide decontamination cycle, single-sided

The challenge

Germfree’s challenge was to design and build a custom isolator that incorporated an attached oRABS unit on the left side for the controlled transfer of raw materials and allowed finished products to exit through the bottom of the chamber via a trapped door lift system, while also integrating a hydrogen peroxide decontamination cycle.

The answer

Germfree’s solution was to design and build a custom 8-foot isolator specifically tailored to Berkshire Sterile Manufacturing’s needs. The isolator’s integrated hydrogen peroxide decontamination cycle allowed for a quick turnaround time for filling small batches while maintaining a sterile environment. The isolator was designed single-sided, providing operators with ample space to work efficiently. The touchscreen interface allowed for easy and precise control of all isolator functions.

Our team also installed a pneumatic lift on the work deck to transfer finished products from the chamber to the airlock. The entire isolator was seamlessly connected to the RABs unit, allowing for streamlined and efficient operation.

The isolator was designed and built from the ground up by our Germfree team and is still used by BSM today, more than six years later. Our solution has enabled BSM to fill small batches in a timely and efficient manner while ensuring the environment remains sterile.

Biopharmaceutical Isolator Gallery

Read about the unique process we used to deliver this project and how we can deliver yours.

Learn about our processYou might also be interested in

Why Mobile and Modular Cleanrooms are Changing the Game in Bio-Manufacturing

Smarthood™: Setting a New Standard in IV Compounding

Smarter Containment: How AI is Reshaping Aseptic Environments

Contact us: Let's unlock your scientific potential together

Complete our contact form and a member of our commercial team will contact you within 24 hours.